....Figure ECS01

....Figure ECS01

Since the first endo filling syringes came out in about 1960 syringe filling and sealing has finally come into its own. Cement filling is generally acknowledged to be well within the standard of care and in fact according to some recent studies to be actually better than gutta percha with cement. (April 2005 Journal of Endo)

We have been preaching this doctrine to all who will listen since 1972 and now that hand instrumentation is passe and there are more forms of gutta percha technique than you can shake a stick at, cement has come into its own.

Since 1982 the material I have been using since 1963 has been certified by the ADA as a "root canal sealer and filler with or without solid core material." In other words, without gutta percha.

Several technological improvements have made syringe filling accurate, simple, predictable and safe.

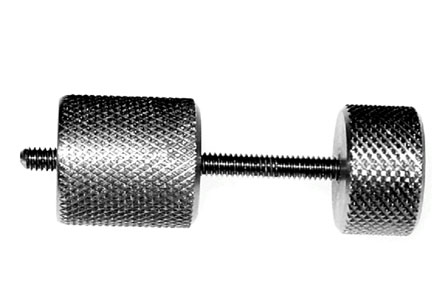

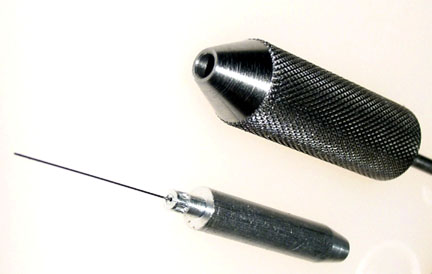

First for practical reasons the syringes must be made of metal, preferably stainless steel to withstand the pressures needed to force a putty-like consistency cement through a needle the internal diameter of which is the size of the tip of a #15 endo file.

Secondly some mechanical advantage must be used because simple pressure as in a hypodermic syringe is both not doable except by someone much stronger than I.

This means either a lever system or a screw system. The finer the screw threads, the more force can be applied and the better control can be exercised.

Whereas with a lever system the smallest amount of movement is the distance between any two ratchet teeth.

With a 40 pitch screw, for instance, if the smallest amount of turn is 1/8 of a turn, the plunger moves 1/8 of 1/40th of an inch the distance is 1/320 or about 0.003 inches, a very small amount.

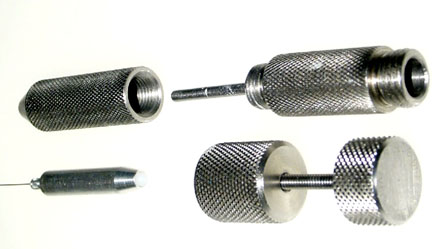

Now the Fine-Cut Endo Cartridge Syringe takes that control to a finer degree by putting the cement into a cartridge which can be loaded separately, keeping the syringe cleaner and making clean-up a matter of throwing the cartridge into the trash.

We make products to last. Most of the syringes we have ever sold (since 1978) are still in use. We expect this one to be no exception.

Threads on distal of cartridge syringe mid-piece match the proximal end threads of the PDL Intraligamentary syringe which can be used as a driver for lighter cements and/or larger needle sizes.

Cartridge fits inside nosepiece.

Another view of the nosepiece.

Video of How to Load the Cartridge

Broad Band Version 900K Video of How to Load the Cartridge

H.261 version Video of How to Load the Cartridge

LoadingCartridgePCAAndBallValveH261.mov

Original helical drive that comes with Cartridge Syringe.

This exploded view shows all the parts of the syringe and cartridge in position.

The thread, namely 5-40 pitch is exactly the same as has been used since 1978 in all the versions of our endo syringes. This means that there need be no technique change for any dentist switching from an older version.

Needle eliminates the need for the washer which was required to seal the older needle against the barrel. Cartridges are aluminum and come WITH a ball valve and thus there is no need for maintaining inventories of ball valves and washers. (Note ball valves and washers are still and will remain available for older versions.)

Cartridge in nosepiece on left and ball driver in midpiece on right. Notice that the end of the driver is hollow ground to match the shape of the ball. This prevents distortion of the ball which in the past caused cement to surge, making this the most accurate syringe yet.

Driver inserted behind ball valve in cartridge.

Closer view of entire syringe with parts separated.

Ball Driver fully extended.

PDL Intraligamentary Syringe (available separately) Still the best, sturdiest and most reliable intraligamentary anesthesia syringe on the market.

E-mail your comments to drjack@BetterEndo.com

....Figure ECS02

....Figure ECS02

....Figure ECS03

....Figure ECS03

....Figure ECS04

....Figure ECS04

....Figure ECS05

....Figure ECS05

....Figure ECS06

....Figure ECS06

....Figure ECS07

....Figure ECS07

....Figure ECS08

....Figure ECS08

....Figure ECS09

....Figure ECS09

....Figure ECS10

....Figure ECS10

....Figure ECS11

....Figure ECS11

....Figure ECS12

....Figure ECS12

....Figure ECS13

....Figure ECS13

....Figure ECS14

....Figure ECS14

....Figure ECS15

....Figure ECS15

....Figure ECS16

....Figure ECS16